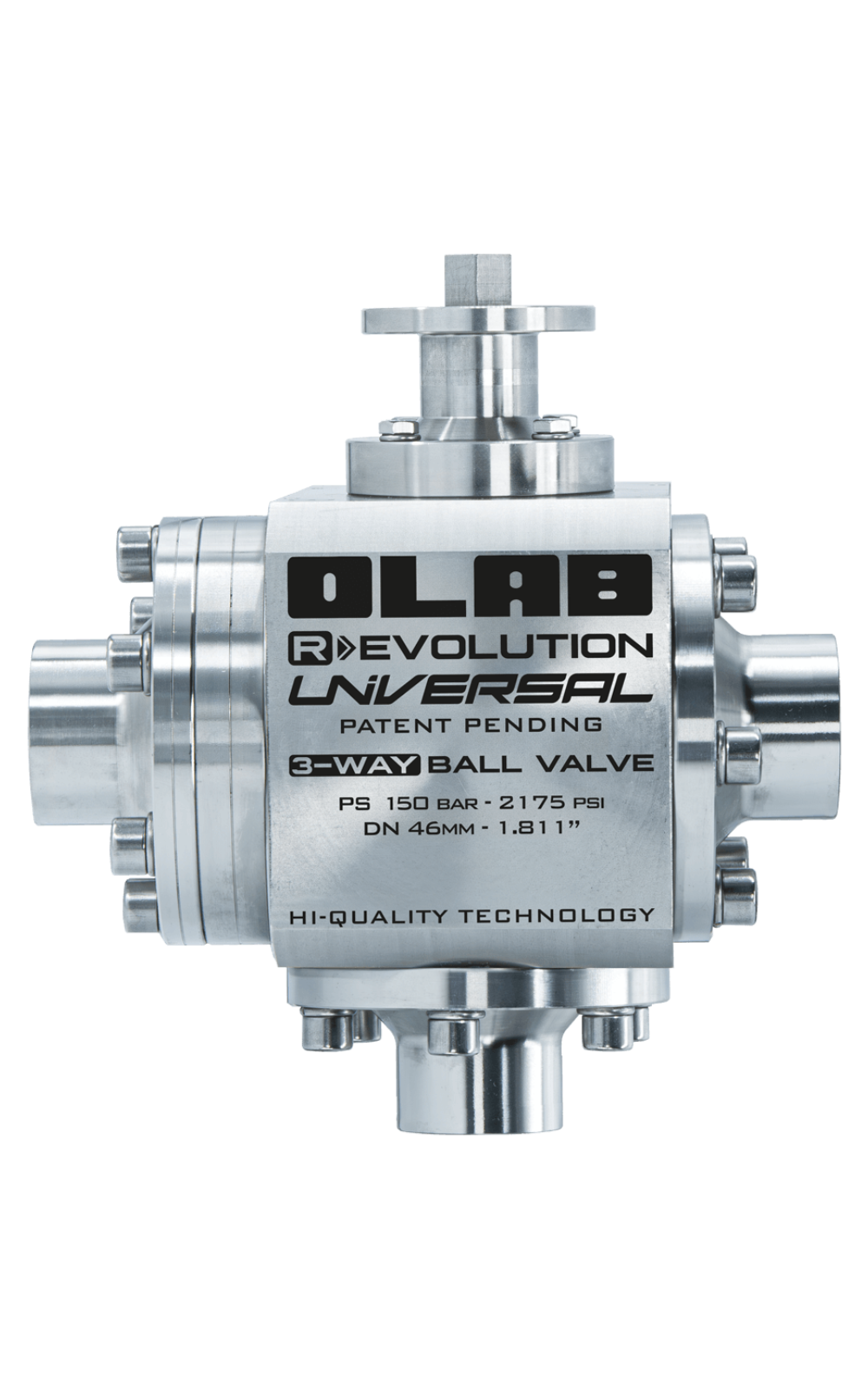

OLAB Series Revolution 3-Way (Patented) is the revolutionary stainless steel flanged ball valve with rotary actuator connection for R744 (CO2) that solves all the problems associated with traditional ball valves with welded or threaded ODS connections, ideal for operation at high pressures (150 bar / 2175 psi guaranteed with a safety factor of 3, burst pressure of 450 BAR / 6527 psi).

The Series Revolution 3-Way is the latest addition to our flanged stainless steel ball valve lineup, crafted specifically for R744 (CO2). The need for such a valve arises from the increasing demands of contemporary systems. This valve is crucial for manufacturing CO2 heat pumps, ensuring high performance with utmost safety.

In fact, the valve body of the Series Revolution is entirely made of stainless steel - anticorrosive and indestructible - and free of welds. It is closed by a series of Class A2 stainless steel screws that screw into the body threads through the flange seats. The perfect seal between these two components is left to a pair of OLAB certified EPDM O.Rings placed in closed housing chambers so as to be anti-extrusion for the seals.

By not having to perform TIG welding to close the valve body, OLAB Series Revolution is not affected by the problems of damage to elastomeric gaskets and seats resulting from possible overheating of the materials. The outer flanges can be easily disassembled and the connecting pipes safely TIG welded before reassembling the flanges. This peculiarity also allows interchangeability of the flanges to change the type of device connections without having to change the entire valve.

One notable advantage of the Series Revolution ball valves is the simplicity involved in replacing the valve body. Welding is a requirement only during the first installation. When the product reaches the end of its life cycle, you can easily unscrew the Class A2 stainless steel screws that connect the valve body to the external flanges, which remain welded to the system. Once the old body is detached, a new body can be inserted in its place and effortlessly screwed back onto the existing external flanges, without the need for additional welding or alterations to the system. This replacement does not require specialized personnel, pipe cutting, or additional welds. This process takes mere minutes and results in significant savings in both time and money, with an added guarantee of safety.

However, our innovations do not end here. We have thoroughly considered every aspect. Whereas traditional end-of-life products need to be discarded entirely, leading to waste and pollution, our Ecosystem approach offers a solution. Valves that are replaced can be returned to OLAB for refurbishment. Here, the internal components can be replaced at a fraction of the cost of a new valve, saving both money and the environment. Choose Series Revolution for a genuinely sustainable system.